From CFD/FEA to AI-Enabled Digital Twin: Predictive Maintenance for High-Criticality Rotating Electrical Machines

1. Introduction

Rotating electrical machines operating in high-criticality environments, such as petroleum refineries, liquefied natural gas (LNG) processing facilities, nuclear power plants, offshore wind installations, and marine propulsion systems, constitute integral components of complex electromechanical systems. These assets interface with variable-frequency drives, hydrodynamic and rolling-element bearings, mechanical seals, thermal management circuits, structural foundations, and process control architectures. Consequently, failure modes propagate through multiple subsystems, where consequential losses extend beyond direct repair expenditure to encompass production interruption, safety incident exposure, and cascading logistical disruption across maintenance planning horizons.

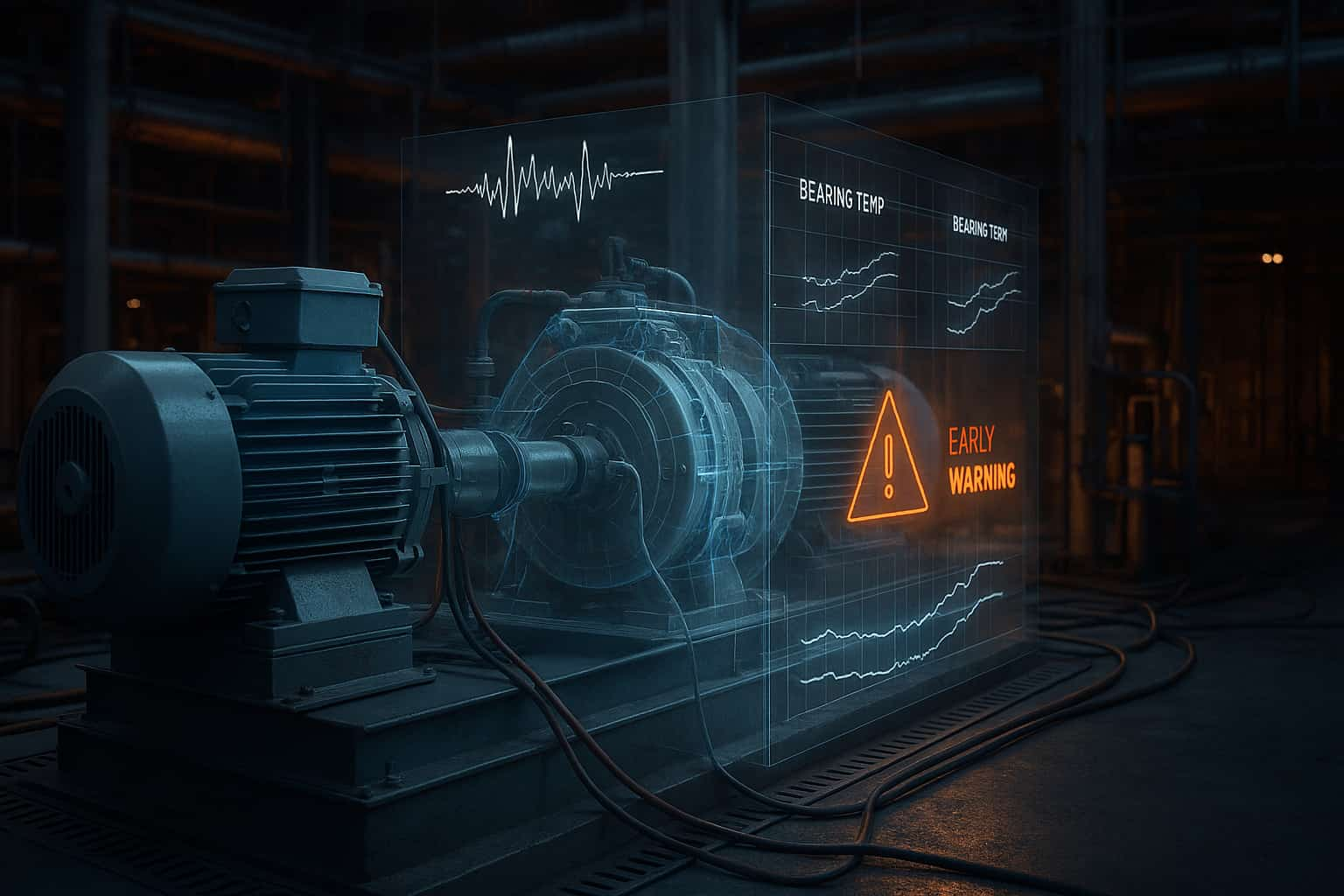

This operational reality has accelerated interest in predictive maintenance methodologies. However, practical implementations frequently encounter performance plateaus characterised by limited sensor deployments, threshold-based alarming with elevated false-positive rates, and insufficient contextual intelligence to support confident decision-making by maintenance personnel. The fundamental limitation lies in the absence of system-specific behavioural context—quantitative understanding of nominal operating envelopes for individual machines under their actual duty cycles, environmental boundary conditions, and degradation trajectories.

A rigorously constructed digital twin addresses this contextual deficiency by establishing a computational framework that integrates physics-based models describing expected machine behaviour, real-time telemetry characterising actual operational states, and analytical algorithms that interpret deviations and generate actionable maintenance intelligence. International standards organisations including ISO and research institutions such as NIST are advancing reference architectures, terminology standardisation, and trust frameworks to enable confident industrial deployment of digital twin technologies.

This technical article presents a systematic engineering methodology for progressing from computational fluid dynamics (CFD) and finite element analysis (FEA) to operational AI-enabled asset-health digital twins for high-criticality rotating electrical machines. The content addresses engineering and operations leadership seeking implementable frameworks encompassing simulation value propositions, instrumentation requirements, data fusion architectures, and pilot deployment pathways that avoid extended implementation programmes.

2. Theoretical Foundation: Why Predictive Maintenance Requires Digital Twin Infrastructure

A fundamental observation underpins the digital twin imperative: identical vibration velocity magnitudes or temperature readings convey substantially different diagnostic significance depending on machine configuration, foundation dynamic stiffness, coupling topology, rotational speed, and operating duty. A bearing housing vibration of 4.5 mm/s RMS may indicate incipient degradation on one machine geometry whilst representing acceptable steady-state operation on another. Similarly, stator winding temperatures of 120°C may constitute thermal margin violation under base-load operation yet fall within acceptable limits during transient overload duty cycles. Reliable interpretation of condition-monitoring data requires machine-specific behavioural models.

ISO 20816 establishes general methodological guidance for vibration measurement and evaluation of machinery, including criteria supporting long-term safe operation and operational limit determination. The standard explicitly acknowledges that both absolute magnitude and temporal change characteristics require consideration, and that evaluation criteria must be "well understood" for the specific machine class and installation. This phrase carries substantial engineering significance: threshold-based alarming without contextual understanding generates nuisance alarms that erode operator confidence and maintenance effectiveness.

The digital twin paradigm addresses this requirement by representing physical assets as dynamic computational models that mirror real-world behaviour and maintain continuous bidirectional data exchange. NIST characterises digital twins as virtual representations of real-world entities enabling monitoring, analysis, and performance prediction, whilst emphasising ongoing research addressing integration methodologies, sensor technologies, model validation, and cybersecurity considerations. The NIST Digital Twins for Advanced Manufacturing programme specifically addresses standardisation challenges for industrial applications.

ISO 23247 provides a reference framework for digital twins in manufacturing environments, establishing terminology, definitions, and general architectural principles. Whilst comprehensive standards expertise is not prerequisite for implementation, the framework enforces disciplined engineering thinking: specification of the twinned asset scope, data acquisition methodology, model update mechanisms, and user application interfaces consuming twin outputs.

The operational distinction is fundamental: sensor systems indicate "something changed"; digital twin infrastructure enables answering "why", "what severity level", and "what maintenance action is appropriate". Without this analytical chain, predictive maintenance programmes oscillate between excessive conservatism generating unnecessary interventions and insufficient sensitivity permitting degradation progression to forced outage.

3. Architectural Definition: AI-Enabled Digital Twin for Rotating Electrical Machines

The term "digital twin" encompasses substantial definitional variation across industrial and academic contexts. For rotating electrical machines in high-criticality applications, a technically rigorous operational definition is: a hybrid computational system combining physics-based modelling representing design-intent behaviour with operational telemetry characterising as-operated reality, employing analytical and machine learning algorithms to transform deviations into maintenance decisions. Implementation fidelity varies across applications; the essential requirement is that twin infrastructure remains grounded in engineering physics rather than purely statistical pattern recognition.

3.1 Three-Layer Architectural Framework

Effective digital twin implementations for rotating electrical machines incorporate three complementary computational layers:

Physics Layer: This foundation comprises reduced-order thermal models calibrated against CFD analysis; vibration sensitivity functions derived from FEA modal analysis and, where applicable, rotor dynamics studies; and electrical loss models correlating with duty cycle parameters. These physics-based representations encode engineering understanding of machine behaviour under varying operational conditions.

Data Layer: The telemetry infrastructure acquires vibration signatures, temperature distributions, current and voltage waveforms, rotational speed, and process load variables. Data acquisition specifications must define sampling frequencies, anti-aliasing filter configurations, calibration procedures, and data quality assurance protocols to ensure analytical validity.

Analytics Layer: The intelligence tier implements anomaly detection algorithms, diagnostic support functions correlating signatures with failure mode hypotheses, and—in mature implementations—remaining useful life (RUL) estimation with quantified uncertainty bounds. As detailed in our article on AI in advanced manufacturing, physics-informed machine learning approaches significantly outperform purely data-driven methods for industrial applications.

NIST research on digital twins for advanced manufacturing emphasises that organisations encounter implementation difficulties not because the conceptual framework is inherently complex, but because they lack clarity on initiation points, model validation methodologies, and output actionability. A layered architectural approach enables incremental capability development with demonstrated value at each stage.

A practical validation criterion for digital twin implementations: can the engineering team utilise the twin to explain causation of observed temperature excursions, predict consequences of duty cycle modifications, and justify maintenance decisions in terms acceptable to both reliability engineers and operations management? Affirmative responses indicate appropriate implementation trajectory.

4. Physics-Based Foundation: CFD and FEA as Reliability Engineering Assets

Computational fluid dynamics and finite element analysis are conventionally categorised as design-phase engineering tools upstream of operational deployment. This perspective represents a significant missed opportunity. Within digital twin architectures, simulation capabilities become reliability engineering assets by systematically identifying: (1) dominant failure mechanism drivers, (2) optimal measurement locations, and (3) operational parameter variations that shift risk profiles.

4.1 CFD: Thermal Field Characterisation, Cooling Margin Quantification, and Boundary Condition Sensitivity

CFD analysis delivers maximum value when thermal management is treated as an integrated system rather than a verification checkbox. For high-criticality rotating electrical machines, the engineering questions are fundamentally practical: Do recirculation zones generate localised hotspots in stator winding regions? What is the sensitivity of winding and bearing temperature distributions to air filter fouling, reduced volumetric flow rates, or elevated ambient temperatures? Do transient duty cycles generate short-duration thermal peaks that existing sensor installations fail to capture?

Digital twin implementations do not necessarily require real-time CFD execution. In most applications, CFD studies inform the development of reduced-order thermal models—computationally efficient approximations that transform readily available measurements (load current, ambient temperature, airflow proxy indicators) into predicted internal temperature distributions and thermal gradients. These predictions establish baseline behavioural envelopes. When measured temperatures diverge from model predictions, the deviation constitutes a meaningful diagnostic signal—one that has already accounted for load and environmental variations.

This methodology exemplifies Rotex Technologies' engineering practice: CFD analysis characterises flow and thermal performance whilst maintaining model validity by incorporating actual installation configurations and operational boundary conditions rather than idealised design assumptions.

4.2 FEA: Structural Integrity Assessment, Modal Characterisation, and Frequency Significance Interpretation

On the vibration analysis dimension, FEA enables progression beyond observational statements such as "spectral amplitude has increased" to mechanistic explanations: "this particular mode is being excited because structural stiffness has changed at this location" or "this resonance frequency exhibits sensitivity to that mounting condition". Engineering practitioners who have investigated vibration anomalies that disappear during controlled testing yet recur in operational service understand the diagnostic value of this capability.

ISO 20816 provides general methodological guidelines for vibration evaluation, but cannot incorporate installation-specific parameters: foundation compliance characteristics, coupling stiffness properties, or site-specific geometric constraints. FEA fills this gap by identifying which vibration modes exist, where strain energy concentrates, and which measurement point locations will most effectively capture diagnostically significant changes. Our comprehensive guide on rotating machinery shock and vibration provides detailed treatment of these analytical methodologies.

Rotex Technologies' service portfolio explicitly encompasses FEA for structural integrity assessment and vibration control applications. In practical deployment, this capability enables field vibration anomalies to be traced to physical root causes—and subsequently translated into monitoring strategies that detect early-stage degradation during future operational cycles.

4.3 Machinery Protection Systems: Digital Twin Complementary Function

High-criticality rotating machinery trains typically incorporate dedicated machinery protection systems (MPS). Standard MPS monitoring scope encompasses radial shaft vibration (proximity probe measurements), casing vibration (accelerometer measurements), axial position, rotational speed with overspeed detection, and critical temperature measurements. The primary objective is safe operation with rapid protective action when threshold limits are exceeded. API Standard 670 provides comprehensive requirements for machinery protection systems in petroleum, chemical, and gas industry applications.

Digital twin infrastructure does not substitute for protection system functionality. The twin operates upstream in the diagnostic hierarchy, detecting subtle degradation trends, identifying combined-signature patterns, and recognising boundary-condition shifts that occur before protection system alarm and trip thresholds are approached. This anticipatory capability reduces forced outage probability without requiring operation closer to safety limits.

5. Instrumentation and Data Infrastructure: Minimum Viable Condition Monitoring Architecture

A single principle should govern instrumentation strategy: prioritise fewer signals with high data quality over extensive sensor deployments with compromised signal integrity. Numerous predictive maintenance programmes fail because acquired data exhibits excessive noise, sampling inconsistency, or insufficient labelling with maintenance outcome records to enable analytical validation. The predictable consequence is operator disengagement from monitoring system outputs.

5.1 Priority Measurement Parameters

Vibration: Bearing housing accelerometers or velocity transducers suffice for most asset classes; proximity probes measuring shaft displacement are appropriate for the most critical machines. Evaluation methodology should align with ISO 20816 guidance to ensure threshold defensibility and cross-installation comparability.

Temperature: Bearing metal temperatures and, where instrumentation permits, stator winding embedded thermocouples or RTDs. Additionally, ambient conditions and cooling system inlet temperatures must be captured as they constitute essential boundary conditions for thermal model validation.

Electrical Signatures: Motor current signature analysis (MCSA) detects a remarkably broad spectrum of fault conditions—broken rotor bars, air-gap eccentricity, certain bearing-related effects, and mechanical load anomalies—using measurements acquired non-intrusively from supply conductors. This approach is particularly valuable where mechanical sensor installation presents access difficulties. The MIT research on nonintrusive MCSA provides rigorous treatment of the theoretical basis and validity conditions for electrical signature diagnostics.

Operating Context: Rotational speed, load or torque proxy measurements, start frequency, process variables (flow rate, pressure, temperature), and drive operating states. Without contextual information, anomaly detection algorithms cannot discriminate between genuine degradation and normal operational variation.

5.2 Data Governance for Analytical Trustworthiness

An uncomfortable engineering reality is that most "AI problems" in condition monitoring applications are fundamentally data problems: sensor calibration drift, firmware version changes affecting signal processing, inconsistent sampling intervals, missing or corrupted timestamps, or absent labelling of maintenance intervention outcomes. NIST publications on digital twin standards repeatedly emphasise requirements for clear specifications, systematic validation procedures, and trust frameworks enabling reliable twin utilisation.

Minimum data governance requirements include: documented acquisition specifications, standardised naming conventions for assets and measurement channels, versioned feature sets ensuring model inputs remain stable, and systematic feedback loops incorporating maintenance outcomes into model refinement. Implementation need not be bureaucratically burdensome—it must be consistent.

6. Analytics Layer: From Anomaly Detection to Remaining Useful Life Estimation

This domain frequently attracts unnecessary complexity. Practical value in industrial condition monitoring derives not from sophisticated algorithmic approaches but from disciplined methodology: define normal operating behaviour, detect deviations from established baselines, provide interpretable diagnostic evidence, and connect findings to maintenance actions.

6.1 Analytically Sound Implementation Stack

Baseline Model Development: Construct normal operating envelope representations as functions of load, speed, ambient conditions, and process variables. This contextualisation is the primary mechanism for reducing false alarm rates in operational deployments.

Anomaly Detection: Monitor residual quantities (measured values minus model predictions) rather than raw measurement values. For example, a temperature residual exhibiting gradual growth over weekly timescales can indicate cooling system degradation even when absolute temperatures remain below alarm thresholds.

Diagnostic Support: Correlate detected patterns with failure mode hypotheses using interpretable features: specific frequency components in vibration spectra, sideband structures in current signatures, harmonic patterns, and known mechanical relationships. Research on MCSA fundamentals demonstrates why sideband components and non-fundamental harmonics carry diagnostic information and how system impedance characteristics affect observable signatures.

RUL Estimation: Once stable baselines and reliable anomaly detection are established, degradation trajectory forecasting and maintenance window planning become feasible—necessarily incorporating uncertainty quantification and human review loops.

The digital twin architecture provides natural guidance toward "physics-informed" analytics. Rather than requiring models to learn relationships entirely from data—rarely feasible given low failure event frequencies—the approach constrains algorithmic behaviour using known physics: thermal transfer relationships, resonance band locations, duty-cycle effects, and protection logic.

6.2 Trust, Explainability, and Regulatory Compliance

In regulated industrial environments, analytical cleverness is insufficient; implementations must be defensible under audit. NIST has explicitly emphasised standards and trust considerations for digital twin technology, encompassing cybersecurity requirements and implementation credibility assessment. Analytics development should incorporate this mindset from inception: interpretable diagnostic evidence, comprehensive audit trails, and formal change control procedures. This aligns with broader trends in AI for engineering applications where explainability is increasingly mandated.

7. Implementation Roadmap: 8–12 Week Pilot Digital Twin Deployment

Organisations awaiting "perfect" architectural solutions will never initiate implementation. A more effective approach executes a pilot deployment on a single high-value asset, demonstrates measurable value, then scales systematically. This approach aligns with observations from major industry surveys, including the Deloitte 2025 Smart Manufacturing Survey: organisations are investing in sensor infrastructure, analytics capabilities, and automation foundations, but maturity gaps persist—particularly in maintenance integration and human capital development—making staged delivery essential.

Phase A — Reliability Problem Definition (Weeks 1–2)

Select a critical asset (motor-driven compressor, pump, fan, or generator) using quantitative criticality scoring methodology. Map dominant failure modes (bearing degradation, insulation ageing, rotor eccentricity, misalignment, cooling system deterioration). Establish success criteria: reduced forced outage frequency, decreased nuisance alarm rates, improved maintenance planning lead times.

Phase B — Data and Physics Baseline Development (Weeks 3–6)

Install or validate minimum sensor configurations; document sampling specifications, calibration procedures, and naming conventions. Develop reduced-order thermal and vibration baselines informed by CFD/FEA analysis (not necessarily full real-time simulation execution). Establish focused dashboards emphasising trends, residuals, and diagnostic evidence rather than vanity metrics.

Phase C — Analytics Integration and Workflow Connection (Weeks 7–12)

Train anomaly detection algorithms using historical operational data; validate against known events and maintenance records. Define alarm philosophy: advisory versus action-triggering indications, required evidence thresholds, and decision ownership. Establish feedback mechanisms ensuring maintenance outcomes improve model performance over time.

Integration into actual work execution processes is the critical success factor. A digital twin residing in a separate "digital" organisational corner will fail to achieve adoption. A twin that assists maintenance planners, reliability engineers, and shift operations teams in making better-informed decisions will be utilised and valued.

8. Implementation Pitfalls and Proven Remediation Strategies

8.1 Pitfall: Treating Implementation as an IT Project

Digital twin implementation is fundamentally a socio-technical undertaking. Engineering leadership must own problem definition and validation because outputs must connect to physical understanding and maintenance decisions. IT functions appropriately enable data flow and cybersecurity—engineering judgement should not be outsourced to technology implementation teams.

8.2 Pitfall: Excessive Sensor Deployment with Inadequate Signal Quality

Prioritise minimal initial deployments with verified data quality. Select measurement locations informed by FEA analysis and known failure mode sensitivities. Align vibration evaluation methodology with ISO 20816 guidance to ensure threshold credibility and benchmarking capability.

8.3 Pitfall: Black-Box AI Without Interpretable Outputs

If analytical models cannot present supporting evidence—trend evolution, residual behaviours, spectral components, current sidebands—outputs will be ignored by operational personnel. In regulated environments, trust and governance are not discretionary enhancements; they constitute implementation prerequisites.

8.4 Pitfall: Disconnection from Maintenance Action

The twin must answer: "What maintenance action is required, and when?" This requires connecting analytical outputs to work order generation, spare parts planning, outage window optimisation, and inspection scope definition. If decision ownership and trigger criteria cannot be explicitly specified, the implementation remains a research exercise rather than an operational capability.

9. Rotex Technologies Capabilities: From Simulation Through Troubleshooting to Digital Twin Outcomes

Rotex Technologies supports clients across regulated and mission-critical industrial sectors with engineering design and analysis of rotating equipment and electrical machines, encompassing high-fidelity CFD and FEA, field troubleshooting, and continuous engineering support. These capabilities translate directly into asset-health digital twin implementations because effective twins require both perspectives: how the machine is designed and constructed, and how it behaves under actual operational conditions.

- CFD Analysis: Thermal margin characterisation, cooling system performance quantification, and boundary condition sensitivity assessment across operational ranges.

- FEA Analysis: Modal behaviour mapping, stiffness sensitivity characterisation, and vibration transmission pathway identification for structural integrity assessment.

- Troubleshooting: Field failure analysis that closes the feedback loop—refining twin models and reducing repeat event probability through root cause understanding. For detailed treatment of vibration analysis methodologies, refer to our technical guide: Ultimate Guide to Rotating Machinery Shock and Vibration. For servo system integration considerations, consult: Servo Motors and Drives—Challenges, Innovations and Future Pathways.

- Digitalisation Services: Comprehensive support for sensing strategy, condition monitoring system design, digital twin architecture, and AI analytics integration for manufacturing and process industry applications. For broader context on AI adoption in manufacturing environments, see: Navigating the AI Revolution in Advanced Manufacturing.

10. Engage With Rotex Technologies

For organisations seeking a pragmatic initial step, we recommend a Digital Twin Readiness Review: asset selection, criticality confirmation, instrumentation gap analysis, physics baseline scope definition (CFD/FEA requirements), and data pipeline/governance outline. This produces an actionable roadmap without commitment to extensive programme structures.

For organisations seeking to reduce forced outage exposure and transition from reactive alarm response to proactive predictive capabilities, Rotex Technologies provides the engineering expertise to shape pilot implementations—grounded in physics-based understanding and field operational reality rather than marketing terminology.

Back to the list