The Progression of Servo Technology: Challenges, Innovations and Future Pathways

1. Industry Overview and Strategic Importance

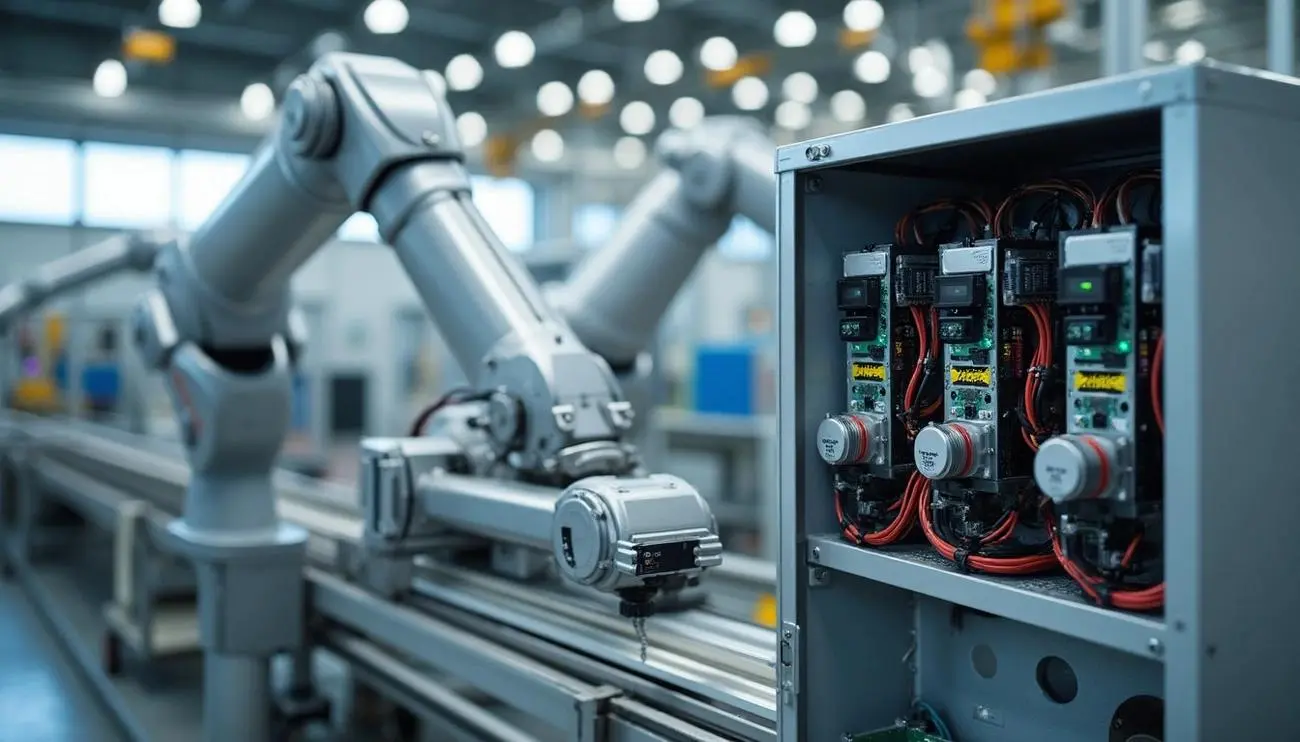

Servo motors and drives form the precision backbone of modern industrial automation, enabling unprecedented control in applications ranging from micro-scale semiconductor manufacturing to massive aerospace systems. The global market, valued at USD 17.20 billion in 2024, is projected to expand at a robust 6% CAGR through 2032, reaching USD 27.42 billion as automation becomes ubiquitous across sectors. This growth is fundamentally fuelled by the relentless drive toward industrial efficiency – servo systems offer up to 60% higher torque capacity versus equivalently sized induction motors while enabling precision unattainable with conventional alternatives.

Regionally, the Asia-Pacific dominates market share and growth velocity, accounting for over 35% of global revenue, driven by China's manufacturing expansion and Japan's robotics leadership . North America maintains technological sophistication with companies like Kollmorgen and Rockwell Automation pioneering next-generation motion control, while Europe excels in high-precision automotive and aerospace applications. The industry's technological pivot is evident in the accelerating transition from DC to AC systems; AC servo motors now command the largest growth segment due to their superior power-to-weight ratios, negligible maintenance requirements, and compatibility with electric vehicle drivetrains.

2. Challenges of Servo Motors and Drives in R&D

The development of next-generation servo systems is a constant battle against physical and technological constraints. Pushing the envelope in one performance metric often introduces trade-offs in others, creating a complex web of engineering challenges that require sophisticated solutions.

2.1 The Dichotomy of Power Density and Thermal Management

The foremost challenge is the perpetual demand for higher power density—more torque and power from a smaller, lighter motor. This is especially critical in robotics and aerospace where weight and space are at a premium. However, increasing power density inevitably leads to a greater concentration of heat. Overheating is a primary cause of premature servo failure, leading to insulation breakdown, bearing lubricant degradation, and irreversible demagnetisation of permanent magnets.

The sources of heat are twofold: copper losses (I2R losses) in the windings, which increase quadratically with current, and iron losses (hysteresis and eddy currents) in the stator core. In compact, high-torque applications, the motor's surface area for convective cooling does not scale with its increased thermal load. Furthermore, protective IP-rated enclosures, necessary for harsh industrial environments, severely restrict airflow, transforming the motor into a well-insulated oven. This thermal bottleneck limits the motor's continuous torque rating and its ability to handle peak loads, directly constraining the productivity of the machinery it drives.

2.2 Material Science and Supply Chain Limitations

The performance of a servo motor is fundamentally defined by its constituent materials, which are now being pushed to their limits.

- Permanent Magnets: High-performance servos overwhelmingly rely on Neodymium-Iron-Boron (NdFeB) magnets for their high magnetic flux. However, standard NdFeB magnets begin to suffer irreversible demagnetisation at temperatures as low as 150°C. Stabilising them for higher temperatures requires the addition of heavy rare-earth elements like Dysprosium (Dy) and Terbium (Tb), which are expensive, and their supply chain is fraught with geopolitical risk. This creates a direct conflict between thermal resilience and cost/supply stability.

- Winding Insulation: The enamel insulation on copper windings is categorised by thermal class (e.g., Class F for 155°C, Class H for 180°C). Exceeding these temperatures causes the insulation to become brittle and fail, leading to short circuits. While higher-class materials exist, they often come with trade-offs in flexibility or cost.

- Mechanical Components: In ultra-high-speed or high-acceleration applications, conventional steel bearings can fail prematurely. While ceramic or hybrid bearings offer superior performance, their high cost limits their widespread adoption.

The Complexity of Advanced Control Algorithms

At its core, a servo drive must execute a control algorithm that is both lightning-fast and perfectly stable. The classic Proportional-Integral-Derivative (PID) controller, while ubiquitous, struggles to cope with the non-linearities inherent in real-world systems, such as friction, backlash in gearing, and variations in load inertia. Tuning a PID loop for optimal performance across all operating conditions has often been described as a "black art."

Modern applications, particularly multi-axis robotics, demand more. They require perfectly synchronised motion, suppression of mechanical vibrations, and adaptive responses to changing dynamics. This necessitates advanced control strategies like feed-forward control, which predicts and compensates for forces before errors occur, and adaptive algorithms that can adjust tuning parameters on the fly. Implementing these strategies demands significant computational power within the drive and a deep understanding of the system's physics, increasing design complexity and cost.

Precision Manufacturing and Quality Consistency

The theoretical performance of a servo motor design can only be realised through exacting manufacturing processes.

- Mechanical Tolerances: The air gap between the rotor and stator is typically measured in fractions of a millimeter. Any inconsistency in this gap can lead to torque ripple and efficiency losses.

- Winding and Assembly: The precise placement of windings within the stator slots is crucial for creating a balanced magnetic field. Automated winding and insertion are essential for consistency.

- Balancing: Rotors for high-speed motors must be dynamically balanced to microscopic tolerances to prevent vibration, which can degrade performance and damage bearings. Achieving this level of precision consistently across mass production is a significant manufacturing challenge, requiring substantial capital investment in automated machinery and rigorous quality control systems, such as automated optical inspection (AOI).

3. Current Technology Landscape and Key Manufacturers

Motor and Drive Topology Advancements

AC servo permanent magnet synchronous motors (PMSM) now dominate 75% of new installations, leveraging high-energy magnets for exceptional torque density and dynamic response. Brushed DC servos persist only in cost-sensitive applications below 1kW, while linear servo motors are gaining adoption in semiconductor lithography with precision capabilities to 50 nanometers . The drive technology evolution centres on silicon carbide (SiC) inverters reducing switching losses by 70% compared to traditional IGBT modules, enabling PWM frequencies above 50kHz for near-sinusoidal current waveforms. Integrated servo-motor-drive units represent the most significant architectural shift, exemplified by Applied Motion Products' MDX+ series which combines all functions in compact housings with plug-and-play commissioning, eliminating cabling-related EMI issues.

3.2 Industrial IoT and AI Integration

Industry 4.0 connectivity has transformed servos from isolated components into intelligent network nodes. PROFINET IRT and EtherCAT protocols enable synchronous motion control across hundreds of axes while transmitting real-time diagnostics. Kollmorgen's AKD2G drives with CIP Sync exemplify this evolution, supporting predictive maintenance through continuous monitoring of torque ripple signatures and winding insulation resistance. Cloud-based analytics platforms like Siemens MindSphere process servo performance data across fleets, identifying degradation patterns invisible to local controllers and optimising maintenance scheduling based on actual utilisation stress rather than time intervals.

3.3 Market Leaders and Competitive Strategies

The servo competitive landscape features three strategic archetypes dominating different performance segments:

- Integrated Automation Giants (e.g., Siemens, Rockwell): Leverage comprehensive automation platforms to offer servo-drive-PLC-MES integration, commanding premium pricing through single-vendor convenience and cybersecurity coherence.

- Cost-Optimised Volume Producers (e.g., Inovance, Panasonic): Dominate consumer electronics automation with standardised servo packages manufactured at unprecedented economies of scale.

In North America market, the manufacturers focus on high-performance applications in medical devices, aerospace, defence and advanced manufacturing sectors. In Europe, EU initiatives like the Green Deal drive demand for energy-efficient motors in precision engineering and sustainability. The technology demands in China is high-volume production of compact servo motors for consumer electronics and EVs. It drives manufacturers on cost-effective mass production and rapid adoption of automation in electronics manufacturing.

4. Servo Technology in Nuclear Applications

Servo motors and drives play critical roles across the nuclear power spectrum, from large megawatt nuclear power plants to small modular reactors (SMRs) and decommissioning facilities, providing precise control and automation essential for safe nuclear operations. In large nuclear facilities, servo motors control steam turbine governing systems that maintain constant rotational speeds regardless of load variations, with control valves using hydraulic servo actuators to regulate steam flow to turbine generators producing electricity at megawatt scale. These systems also drive reactor coolant pumps, feed water pumps, and condensate pumps, where variable frequency drives (VFDs) have demonstrated energy savings from 70% to 95% efficiency while reducing electricity consumption by up to 50% through precise speed control. Control rod drive mechanisms utilise servo motors for fine motion control, enabling precise positioning of neutron-absorbing rods to manage reactor power output and ensure safe shutdown capabilities. These applications demand extreme reliability, deterministic response, resilience to radiation, temperature, and seismic events, adhering to stringent standards like RCC-E, IEEE 323/344. In SMRs, which deliver 5-300 MWe per module, servo systems provide similar functions but at smaller scales while maintaining the same precision requirements for safety and operational control. Nuclear decommissioning operations extensively employ radiation-resistant servo motors in robotic manipulators and remote handling systems, where robots equipped with servo-driven joints perform hazardous tasks like fuel debris retrieval, radioactive waste handling, and facility dismantling operations. These specialised servo systems must withstand extreme environmental conditions including high radiation levels up to 106 Gy, temperatures ranging from -196°C to 250°C, and operate reliably in contaminated environments where human intervention is impossible.

5. Servo Technology in Next 5-10 Years

The next decade promises transformative changes in servo technology, driven by innovations across four key areas.

5.1 Generative and Integrated Design

The design process itself is being revolutionised. Generative design software, powered by AI, will be used to create topologically optimised motor housings and components that are drastically lighter than human-designed parts while maintaining or even increasing structural rigidity. Additive manufacturing (3D printing) will move from prototyping to production, enabling the creation of these complex geometries, e.g., cooling channels. A key application will be printing motor housings with intricate, conformal cooling channels directly embedded within the structure, allowing for highly efficient liquid cooling and pushing power density to new heights. The trend of integration will also accelerate, leading to highly compact "smart motor" modules that combine the motor, encoder, drive, gearbox, and even safety logic into a single, plug-and-play unit with high cost for niche product.

5.2 Advanced Materials

The reliance on performance-limiting and supply-chain-vulnerable materials will be a primary focus of innovation. Research is intensifying on rare-earth-free magnets, such as advanced ferrites and manganese-based compounds, to mitigate cost and supply risks. While their performance does not yet match NdFeB, the gap is closing for many applications. For high-performance needs, new magnet formulations will increase the maximum operating temperature well above 200°C. Nanocomposite insulation materials are being developed that blend polymers with nanoparticles to dramatically improve both thermal conductivity and dielectric strength. This allows heat to be extracted more effectively from the windings. On a longer horizon, the development of technologies like carbon nanotube windings could offer superior conductivity and lighter weight than copper. New Soft Magnetic Composites (SMCs) and amorphous metal alloys will enable motors to operate at higher frequencies with significantly lower iron losses, which is critical for efficiency in high-speed applications.

5.3 AI-Driven and Predictive Control

The intelligence within the servo drive will experience a quantum leap. AI and machine learning will become standard features, moving beyond auto-tuning to create truly adaptive control. Drives will use reinforcement learning to continuously optimise their own control parameters in real-time, responding instantly to changes in load, friction, or wear. The most significant shift will be the integration of predictive maintenance directly into the drive. By analysing subtle changes in current, vibration, and temperature signatures, the drive will be able to diagnose developing problems—such as bearing wear or misalignment—and predict the remaining useful life of the motor, sending alerts long before a catastrophic failure occurs. This will be enabled by edge computing, with powerful processors embedded in the drive performing this analysis locally, reducing network latency and providing instantaneous feedback in multi‑axis coordination.

5.4 Smart Manufacturing

The way servos are produced will become as intelligent as the products themselves. Every motor design will have a corresponding digital twin—a high-fidelity virtual model. This twin will be used to simulate performance and optimise the design before any physical parts are made. The twin will then be linked to the physical motor throughout its life, with real-world operational data being fed back to refine the model and inform the design of future generations. Manufacturing lines will become more Intelligent, flexible and automated, using collaborative robots and AI-powered vision systems to manage assembly and quality control, enabling cost-effective production of highly customised motor variants. Circular Economy and Sustainability will become a key design criterion. This includes designing motors for easy disassembly and refurbishment. More importantly, manufacturers will invest in technologies for the recycling and recovery of critical materials, especially rare-earth elements from end-of-life magnets, creating a more resilient and environmentally friendly supply chain.

6. Conclusions

The servo motor and drive industry is at a pivotal juncture. The challenges of increasing power density, managing thermal loads, overcoming material limitations, and mastering control complexity are formidable. Yet, they are also the crucibles of innovation. The current technological landscape, built on the foundation of PMSMs, intelligent drives, and real-time networking, is already a testament to decades of progress. The strategies of leading manufacturers reflect a mature and competitive market, pushing for both incremental and breakthrough advancements.

Looking forward, the trajectory is clear: the silo approach to development is obsolete. The future belongs to those who can master multidisciplinary integration, seamlessly blending advanced materials science with generative design, AI-driven control algorithms, and sustainable, digitised manufacturing. The servo motor will evolve from a simple component into a self-aware, intelligent cyber-physical system capable of optimising its own performance, predicting its own failures, and collaborating seamlessly with other systems. As industries worldwide continue their march towards greater automation, efficiency, and intelligence, this new generation of servo technology will not just be a participant; it will be a primary and indispensable enabler of that future.

Back to the list