UK SMEs Collaborate to Deliver Digital Manufacturing Study for Sellafield

February 2026 · Rotex Technologies

Rotex Technologies and Bloc Digital have delivered an advanced manufacturing feasibility study for Sellafield Ltd, showcasing how UK SME collaboration through the LINC with Sellafield Ltd scheme can support the nuclear sector’s decommissioning mission.

Sellafield Ltd requires more than 35,000 stainless steel waste containers across multiple product variants to support its decommissioning and waste management programmes. To achieve this volume efficiently, Sellafield is evaluating the establishment of a dedicated Final Assembly Line (FAL) facility, a first-of-its-kind approach that would receive standardised and bespoke component parts and assemble complete packages aligned with project milestones.

Collaboration between UK SMEs

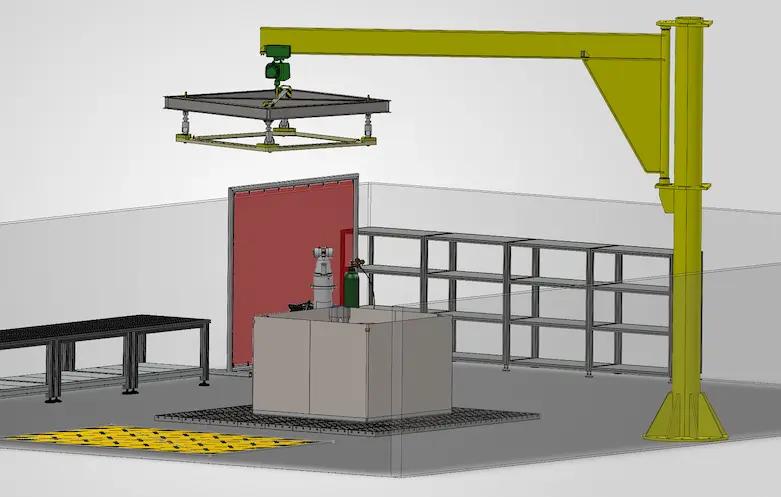

The project brought together complementary expertise from two UK SMEs. Rotex Technologies provided engineering design and analysis expertise, including manufacturing process evaluation, feasibility assessment, and production optimisation recommendations, drawing on experience in regulated industries. Bloc Digital delivered cutting-edge 3D visualisation and virtual reality (VR) modelling, transforming engineering concepts into immersive digital environments that enable stakeholders to explore and refine the proposed assembly line before physical implementation.

The project exemplifies how the LINC scheme enables SMEs to access opportunities within the UK’s nuclear supply chain. By combining specialist engineering consultancy with digital innovation capabilities, the collaboration delivered high‑quality outputs that meet stringent nuclear sector requirements while demonstrating the agility and innovation that SME partnerships can offer.

What our partners said

“This project represents exactly the type of collaboration that strengthens the UK's nuclear supply chain whilst advancing our collective capabilities. By partnering with Bloc Digital, we've combined deep engineering domain expertise with state‑of‑the‑art immersive technology to deliver a solution that enables Sellafield to visualise and optimise their Final Assembly Line concept before committing to physical infrastructure.

The project aligns perfectly with our mission of ‘Electrifying towards NetZero’, supporting the UK's clean energy infrastructure through advanced engineering and digital transformation. We look forward to continuing our work with Sellafield and building on this successful partnership with Bloc Digital.”

“This project shows how immersive digital tools can make a real difference when you’re dealing with complex manufacturing in a highly regulated environment. By turning engineering data into an interactive 3D and VR model of the Final Assembly Line, we helped teams understand layout, workflow, and constraints early on. We believe this will give Sellafield the confidence to explore and refine the concept before committing to physical infrastructure.”

“Sellafield Ltd commissioned the study to support the Manufactured Products Organisation (MPO) strategy for developing high‑volume, repeatable manufacturing routes for future waste containers. As the Intelligent Customer for volume manufactured products, the MPO applies a structured New Product Introduction (NPI) process to mature product and process definitions through gated phases, drawing on industry methods such as APQP to reduce technical and supply chain risk.

The feasibility work delivered by Rotex Technologies and Bloc Digital supports early NPI phases by assessing manufacturability, production flow and supply chain capability. The use of immersive VR modelling aligns with the MPO focus on Design for Manufacture and Design for Assembly, enabling evaluation of layout, throughput and process constraints before committing to physical facilities.

The study also contributes to MPO’s ambition to build a stronger, more repeatable UK supply chain for high‑integrity products. By examining how component manufacture across multiple suppliers can converge into a dedicated Final Assembly Line, the work reflects MPO principles of standardisation, predictable delivery performance and assured quality achieved through evidence such as PFMEA, control plans and validation activity.

Overall, the collaboration provides early insight into how a modern, digitally enabled assembly environment could support Sellafield’s long‑term mission, while demonstrating the value SME partnerships can bring to building capability and maturity across the UK supply chain.”

Next step – Phase 3 development and future implementation

Building on the successful delivery of the feasibility study and 3D/VR concept model, Rotex Technologies and Bloc Digital will now proceed to Phase 3 of the programme. This final phase will refine the immersive VR concept to further optimise assembly time and throughput, whilst developing preliminary designs for bespoke equipment and tooling required for the FAL. The team will conduct location analysis considering logistics, workforce availability, and infrastructure requirements, and propose layout adjustments to mitigate any identified bottlenecks. A comprehensive health and safety review will specify necessary controls and any special requirements for the facility. This work will provide Sellafield with the detailed roadmap needed to progress the FAL concept towards realisation, supporting efficient delivery of stainless‑steel waste containers critical to the UK’s nuclear decommissioning mission.

About Rotex Technologies

Rotex Technologies Ltd is a UK‑based engineering design and consultancy company specialising in industrial machinery, rotating equipment, manufacturing process and sustainable energy solutions.

With over 25 years of combined experience, the team delivers advanced engineering design solutions, CFD and FEA simulation, technical consultancy, and R&D partnerships across nuclear, renewable energy, oil and gas, and advanced manufacturing sectors.

The company is committed to driving digital transformation and supporting the UK's NetZero ambitions.

Website: rotextechnologies.com

About Bloc Digital

Bloc Digital is a UK‑based immersive technology company specialising in 3D visualisation, virtual reality, and digital twin solutions for industrial applications.

Their expertise spans aerospace, aviation, defence, education, engineering, industrial, manufacturing and rail sectors, helping organisations visualise complex systems

and optimise operations through cutting‑edge digital experiences.

Website: bloc.digital

About Sellafield and LINC

Sellafield Ltd is responsible for safely delivering decommissioning of the UK's legacy nuclear facilities, managing the country's most complex nuclear challenges.

The LINC with Sellafield Ltd scheme encourages SMEs at local and national level to collaborate and deliver innovative solutions to the mission at Sellafield,

enabling smaller companies to compete for contracts and collaborate on projects that support the UK's nuclear decommissioning and clean energy programmes.

Website: Sellafield Ltd (GOV.UK)

Press & media enquiries

For story, images, or further information, please contact us.