The Evolution of Motors and Drives in Humanoid Robotics

1. Introduction

The field of humanoid robotics stands at the intersection of mechanical engineering, artificial intelligence, and materials science. They are rapidly transitioning into real-world applications from healthcare and customer service to industrial automation and disaster response. At the heart of these increasingly capable machines are sophisticated motors and drive systems — the critical components that enable precise, adaptive, and human-like movements and interactions. As humanoid robots evolve to mimic human dexterity and agility, the demand for advanced motor technologies has surged.

2. Global Market Outlook and Growth Trajectory

The humanoid robot market is experiencing unprecedented growth, driven by technological breakthroughs and substantial government investments across major economies. According to recent market analyses, the global humanoid robot market was valued at USD 2.21 billion in 2023 and is projected to reach an impressive USD 76.97 billion by 2032, growing at a compound annual growth rate (CAGR) of 48.36% over the forecast period. This remarkable expansion reflects the transition of humanoid robots from experimental prototypes to practical solutions in diverse sectors.

In parallel, the robotics and automation actuators market-a critical component sector for humanoid development-is expected to grow from USD 27.79 billion in 2025 to approximately USD 87.69 billion by 2034, at a CAGR of 13.65%. This growth is fuelled by increasing automation across manufacturing industries and the rising adoption of robotics technology in various applications.

Several countries are spearheading this robotic revolution with strategic initiatives. Japan, facing demographic challenges with its ageing population, has implemented government-backed programs to introduce elder care robots. China's "Made in China 2025" initiative prioritises robotics to enhance industrial automation capabilities, while the United States has directed significant investments toward defence and healthcare robotics applications, with DARPA playing a crucial role in advancement.

3. The Crucial Role of Motors and Drives in Humanoid Functionality

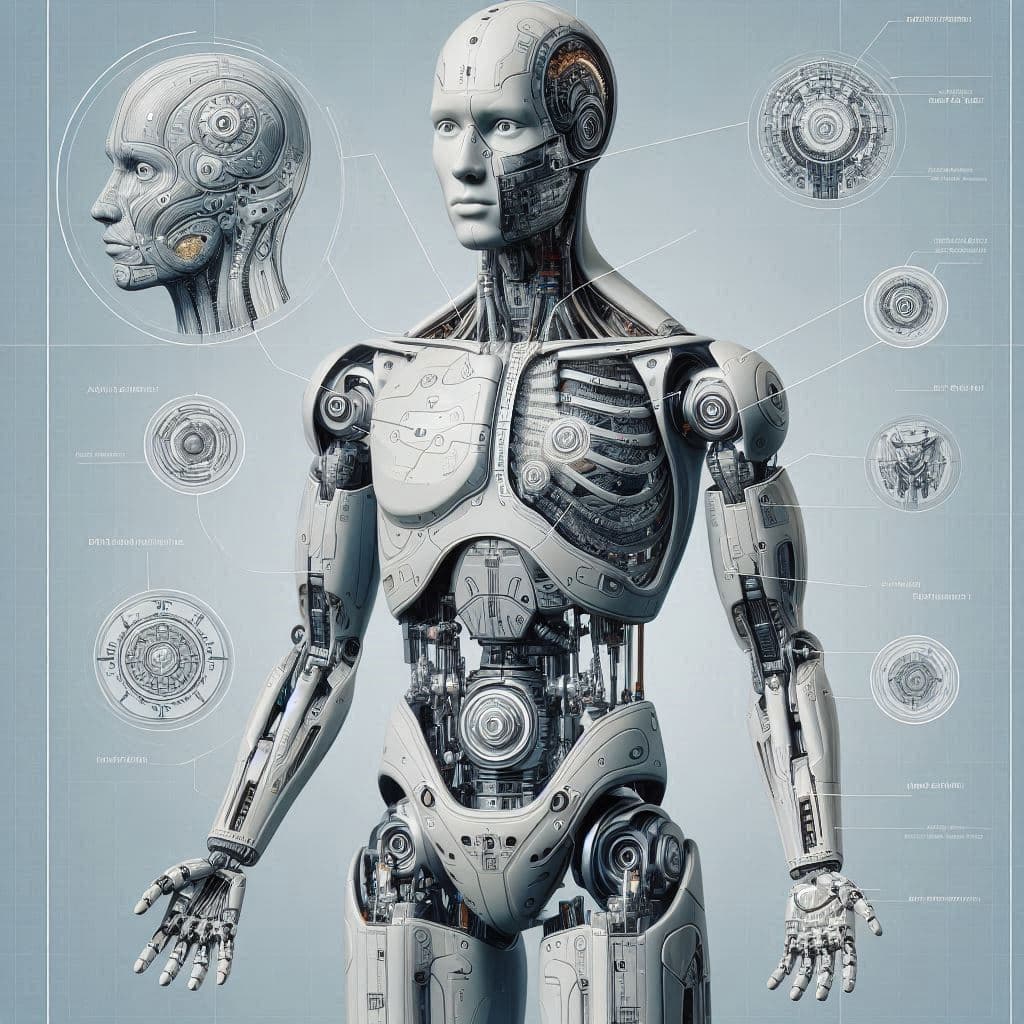

The ability of humanoid robots to execute fluid, precise movements hinges on their actuation systems. Actuators in humanoid robots function as artificial joints and muscles, transforming electrical signals into mechanical motion that mimics human movement capabilities.

Actuators in humanoid robots consist of several integrated components: gears, motors, sensors, ball bearings, and encoders that work in concert to produce controlled movements. The complexity of humanoid robots is reflected in their degrees of freedom-current models feature between 16 and 60 degrees of freedom, each requiring dedicated actuators to enable sophisticated motion patterns. Five critical factors determine motor selection for humanoid applications:

- Precision: Motor precision directly impacts the robot's positioning accuracy. Even minimal deviations in individual joints can accumulate into significant misalignments. The precision of electric motors increases with the number of pole pairs, which directly affects control, positioning, and regulation capabilities.

- Reaction Time and Dynamics: For humanoid robots to navigate dynamic environments effectively, motors must deliver excellent response times and dynamic control. This requires high torque generation for short durations-known as peak torque or overload capacity-which allows robots to quickly adjust to unexpected terrain changes or obstacles.

- Power-to-Weight Ratio: Given the strict weight constraints in humanoid design, motors must deliver maximum power while maintaining minimal weight.

- Control Accuracy: Precise control across varying speeds and loads enables the smooth, natural movements expected from humanoid robots.

- Energy Efficiency: Battery-powered humanoid robots require highly efficient motors to extend operational periods between charges.

4. Types of Motors and Drives Dominating Humanoid Robotics

4.1 Coreless Motors

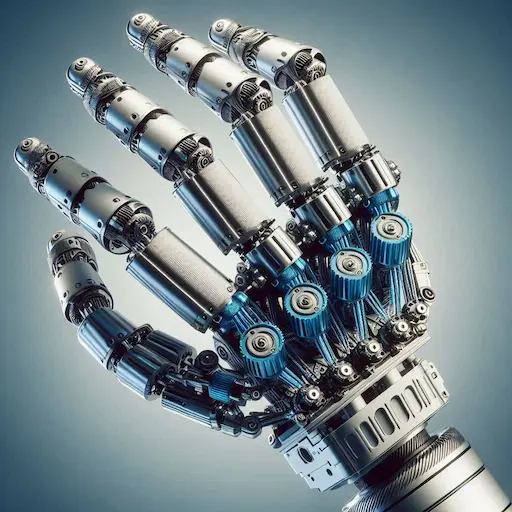

Coreless motors have emerged as critical components in humanoid robotics, particularly for applications requiring precise movements. Unlike conventional motors with iron cores, coreless motors (also called cup motors) feature a unique rotor structure that eliminates cogging torque and provides superior dynamic response. In humanoid robots, coreless motors serve different functions depending on their placement:

- Frameless torque motors are typically used in the torso for broader movements

- Coreless cup motors are employed in dexterous hand joints where fine manipulation is required

Their high efficiency, precision, and compact design make them ideal for applications requiring agility and accuracy. Tesla's Optimus robot, for example, utilises coreless motors for its hand movements, enabling delicate object manipulation.

4.2 Harmonic Reducers

Harmonic reducers have become the mainstream choice for humanoid robot joints due to their exceptional performance characteristics. These sophisticated components convert the high-speed rotation of motors into low-speed, high-torque output-essential for stable and powerful support of robotic joints. The core components of harmonic reducers include: Wave generator, Flex spline (flexible gear), Flex bearing.and Rigid spline (rigid gear).

These reducers offer multiple advantages for humanoid applications:

- Compact size and light weight (reducing volume by 2/3 and weight by half compared to conventional reducers)

- Large transmission ratios (single-stage ratios from 70 to 500, with some reaching 1000)

- High motion precision with minimal transmission errors

- Potential for zero-backlash engagement, ideal for precise bidirectional movements

5. Current Technology Landscape and Key Market Players

The market for motors and drives in humanoid robotics features established industry leaders alongside emerging innovators. In the coreless motor segment, Switzerland's Maxon and Portescap, along with Germany's Faulhaber, collectively hold over half the global market share. However, Chinese manufacturers like Mige Electric and Topband are gaining ground with competitive offerings.

Recent innovations are making humanoid robotics more accessible than previously possible. The Berkeley Humanoid Lite represents an open-source approach that utilises 3D-printed gearboxes for actuators and robot structures. This design adopts a cycloidal gear configuration that optimises form factor while keeping hardware costs under $5,000 based on U.S. market prices.

In the commercial sector, notable examples of advanced humanoid robots include: Tesla's Optimus robot for manufacturing and logistics applications, Xiaomi's Iron Man and UBTech's WalkerX which demonstrate sophisticated motion control systems, and Industrial humanoid robots developed by companies like FANUC and ABB, which are being integrated into production environments.

6. Technological Challenges and Limitations

Despite significant advances, several challenges persist in motor and drive technology for humanoid robots:

- Material Limitations: 3D-printed components, while improving accessibility, still present durability and strength challenges compared to metal alternatives, particularly under high-stress conditions.

- Precision vs. Cost Tradeoffs: Achieving the necessary precision for human-like movements often requires expensive components, limiting widespread adoption.

- Power Management: The high power requirements of multiple actuators create thermal management challenges and battery life limitations.

- Environmental Adaptability: Motors must maintain performance across varying conditions, from smooth indoor surfaces to uneven outdoor terrain.

- Weight Constraints: Powerful motors with adequate torque tend to be heavier, compromising the robot's agility and efficiency.

7. Emerging Trends and Future Directions

Several promising trends are shaping the future of motors and drives for humanoid robots:

8. Conclusion

The technological development of motors and drives for humanoid robots represents one of the most dynamic and promising fields in modern robotics. As market projections indicate exponential growth over the coming decade, innovations in actuator design, materials science, and manufacturing approaches are converging to create increasingly capable and accessible humanoid platforms.

The evolution from experimental prototypes to practical applications across healthcare, manufacturing, service, and space exploration sectors demonstrates the transformative potential of these technologies. While significant challenges remain in achieving truly human-like movement capabilities at reasonable cost points, the rapid pace of innovation suggests that the gap between science fiction and reality is narrowing with each technological advancement.

As motors and drives continue to improve in precision, efficiency, and power-to-weight ratios, humanoid robots will increasingly complement human capabilities in complex environments, potentially revolutionising how we approach everything from elder care to disaster response and industrial manufacturing.

Back to the list